As usual, I had to do my expo floor visit at a near running pace, but I still found a few inspiring items to share. While there were some beautiful parts on display, I am also inspired by companies with unique business models that allow them to serve early stage companies.

Punch & Die

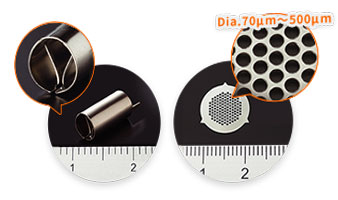

Some say that any sufficiently advanced technology is indistinguishable from magic, I would say that any old technology sufficiently refined is magic as well. JKB Co., based in Japan, produces die-stamped parts that look impossible to have made without a laser. 1-2 million parts off a single tool with no loss of precision.

Breakaway 3D Printed Molds

The benefit of 3D printing a mold is the rapid turn-time and reduced material costs, however the fundamental geometry benefits of 3D printing are lost. Addifab is putting this back in by creating an injection mold tooling material that can be broken away after the part material has been injected and cooled. Small parts, impossible geometry, impossible materials.

Teeny Tiny Engineering

When you need to keep physicists on your team and microscopes at your trade show booth, you know your parts are getting small. Xidas is a company specializing in the engineering of incredibly tiny sensor devices. The image above is an implantable, zero power sensor used to track glaucoma.

Molding for Precision Fluidics

Microfluidics is extremely hot in diagnostic technology right now. However, most start-ups may not realize just how specialized the molding equipment is to produce the parts reliably. It all looks reasonable in CAD. Natech Plastics is a molding company that understands just what it takes to make the parts meet the specification at that scale.

Catheter Shaft Engineering

Catheter shafts are another area where a seemingly simple part (a flexible tube) requires an intense amount of specialized knowledge to engineer and produce. However, most large supplier run their part extruders in the 1000's of feet for a single lot. Cardea Catheter Innovations is a small, expert shop with its own extruding equipment, clean rooms and a mission to support early stage companies developing their product.

Comments